Matech Oem Custom Industrial Metal Alloy Steel Forging Sprocket

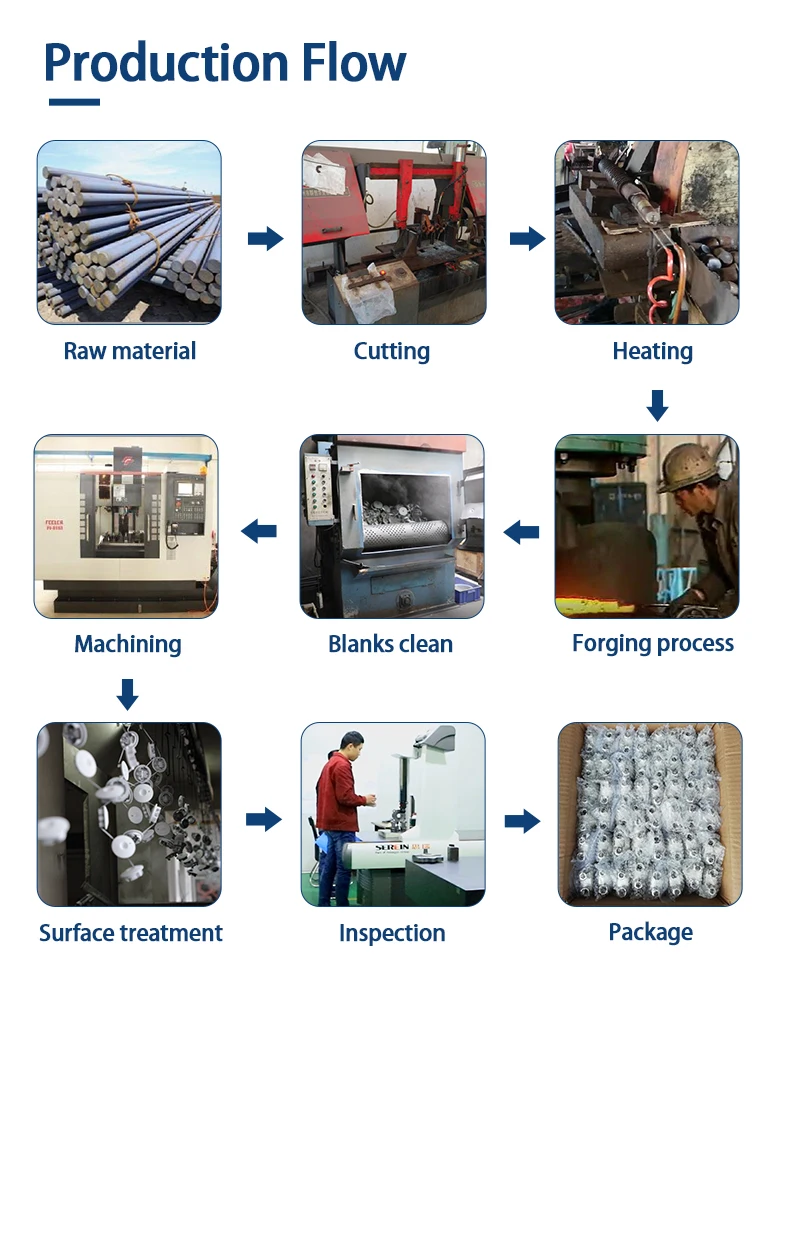

- Process:Forging+Machining(if Need)+heat treatment +surface treatment

- Surface Finished:Sandblasting, painting, polishing or as customer's requirements

- Material:carbon steel, alloy steel, stainless steel or as requirements

- Certificate:ISO,or as customer's needs

- If you have project that requires customized parts, could you please send us the drawings or samples of the product? We are happy to quote you.

Matech Oem Custom Industrial Metal Alloy Steel Forging Sprocket

SINCERITY QUALITY COMPETENCE ENTERPRISING

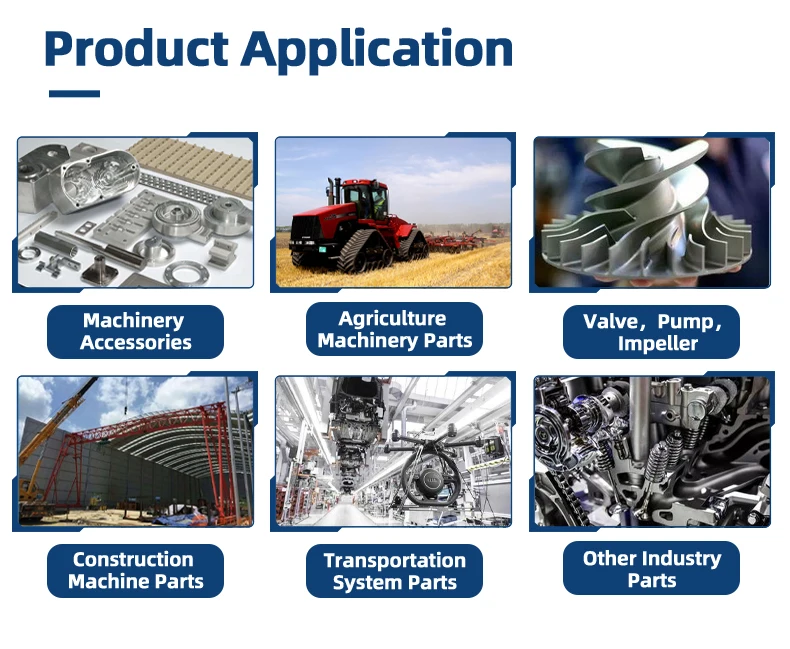

Products Description

Contact Us

FAQ

Click to see more details