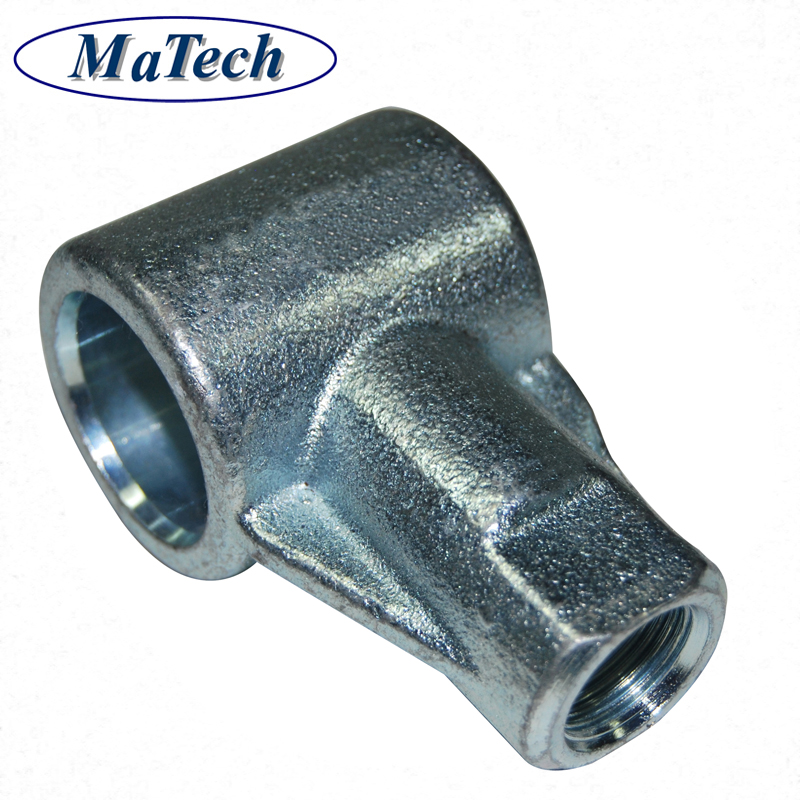

- Size:customized size

- Material:Steel, carbon steel, stainless steel, as customer's requirments

- Surface Treatment:Painting, Zinc plated or as client require

- Manufacture Process:precision investment casting, lost wax casting

- Lead time: around 45 days for stainless steel castings

- Package:Multi-layer wooden box/pallet, with big plastic bag inside

Custom Precision Parts Steel Casting From Factory

Custom Precision Parts Steel Casting From Factory

Item Name | Custom Precision Parts Steel Casting From Factory |

General Products Application/Service Area | Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, transportation equipment, Valve and Pump system, Agriculture machine metal Parts, engine bracket, truck chassis bracket, gear box , gear housing , gear cover, shaft, spline shaft , pulley, flange, connection pipe, pipe, hydraulic valve , valve housing ,Fitting , flange, wheel, fly wheel, oil pump housing, starter housing, coolant pump housing, transmission shaft , transmission gear, sprocket, chains etc. |

Main blank Process for Steel Casting |

Investment casting (wax mold made by middle temperature wax) /Precision casting ; Lost Wax Casting (wax mold made by low temperature wax)/ Precision casting;

|

Blanks Tolerance -Casting Tolerance | CT7-8 for Lost wax Casting Process CT4-6 for Investment casting Process |

Applicable Material for our steel casting factory | Carbon steel, Low Carbon steel, middle carbon steel, G35, G45, WCB, WCA, WCC, ISO 340-550,

Alloy Carbon steel: G25CrMo4, Heat Resistant Steel,

Stainless Steel: CF8, CF8M, . G-X6CrNiMo1810, G-X7CrNiNb1189, SUS 304, 304L, 316, 316L.

OR According to customer requirement |

Casting Blank Size /Dimensions | 2 mm-600mm / 0.08inch-24inch according to customer requirement |

Casting Blank Weight | Range from 0.01kg-85kg |

Applicable Machining Process |

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming /Grinding/Honing and etc.

|

Machining Tolerance | From 0.005mm-0.01mm-0.1mm |

Machined Surface Quality | Ra 0.8-Ra3.2 according to customer requirement |

Applicable Heat Treatment |

Normalization , annealing, quenching and tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching

|

Applicable Finish Surface Treatment | Shot/sand blast, polishing, Surface passivation, Primer Painting , Powder coating, ED- Coating, Chromate Plating, zinc-plate, Dacromat coating, Finish Painting, |

MOQ of mass production | For casting steel products: 100pcs, or as customer required For machining: 50pcs |

Lead Time | 45 days from our steel casting factory |

We produce steel casting parts per your drawing or sample, with cost reduction and feasible tech proposals. Inquiry now!