Customized Permanent Mold Casting Aluminum Gear Case

- Material:ZL101, AlSi7Mg, A356 or as client require

- Process:Casting +Machining(if Need)+surface Treatment

- Surface Finished:Sandblasting, painting, polishing or as customer's requirement

- Drawing Format:pdf,stp,step,etc

- Delivery time:For sample about 45 days of casting aluminum

Customized Permanent Mold Casting Aluminum Gear Case

SINCERITY QUALITY COMPETENCE ENTERPRISING

Products Description

Technique Process

Raw material

100% pure aluminum ingot

Machining plant

Machining

vertical machining center

Open The Die

Open the die based on your technical drawings or samples.

Mold material:High quality steel material

manufacturing:Full machining

finished tooling:about 25 days to machining tooling

Low pressure casting

Low pressure casting

Surface treatment: Sandblasting

Surface treatment:Powder coating process

Matech custom surface treatment based on your requirements

Main Parts

Product packaging

Company Profile

Shanghai Matech Machinery Manufacture Co., Ltd.

--Branch of Matech Industry Ltd.

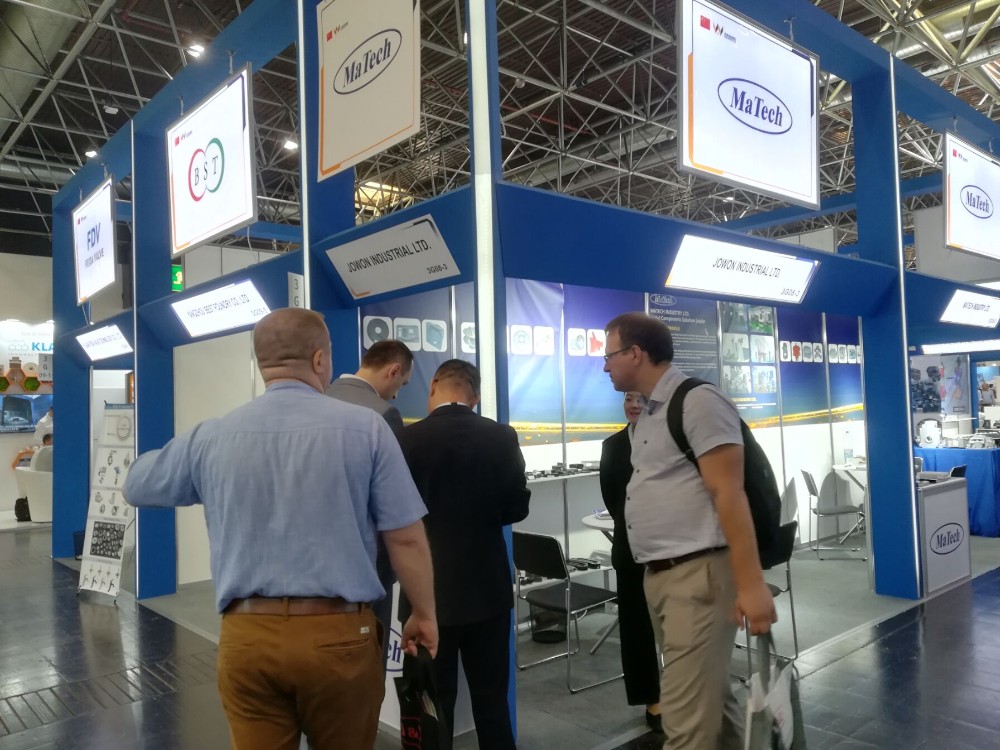

Matech attend the GIFA 2019 in Germany

Matech attend the GIFA 2019 in Germany

Our Team are a big happy family, we not only supplying products to our customers , but also trying to build more values to our customers’ business by introducing suitable solution or technology to our customers with compromising parts’ function,technologies’ advantage, realization feasibility, cost control and quality reliability.

Customer Photos

Excellent customer service and pricing, very happy with the product and quality. MATECH is very good to deal with will continue to do business.

l am very happy that MATECH give me a very good service. Nice commumication and updating the process frequently.

The parts look like very nice.The machining positions tolerance is well controlled. For critical dimensions,our engineers checked,it is same as inspection report.

One of the best services.From the beginning of

product design, the factory has been providing

the best quality service,has been patient to

answer our questions.

They are very good at custom metal parts based

on our drawings.Very professional at casting

services.Easy to communicate & understand!

l highly recommend Matech industry ltd. company, they are very professional and committed to delivering quality work and services.The supplier is very professional,the quality for our custom casting chassis bracket and gear housing are very perfect,and the timely delivery.

FAQ

We are a professional manufacturer with over 15 years‘ export experience