- Material:Cast Iron GGG50, GGG60 etc. As customers request

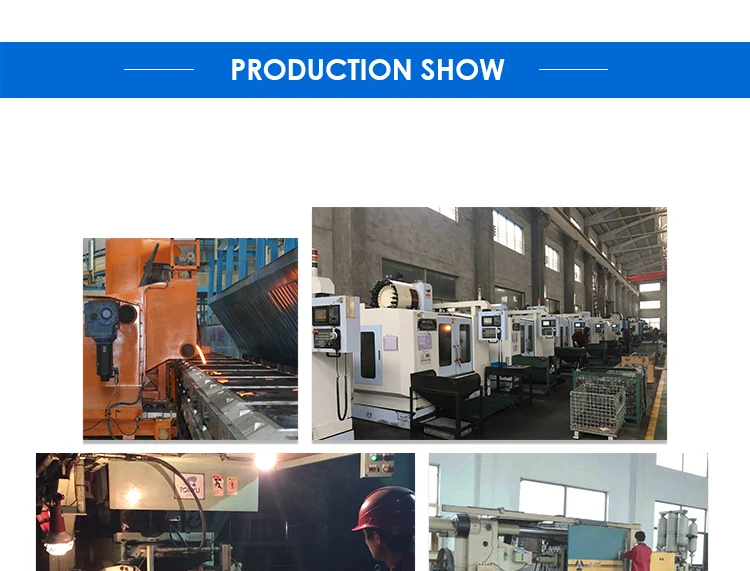

- Manufacturing Process: Sand casting, cast iron

- Casting Tolerance: CT9-11 for cast iron

- Machining Process: CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling etc.

- Surface treatment: Dacromat Coating, Finish Painting etc. As customers request

- Package: Multilayer wooden box/pallet, with big plastic bag inside

- Lead Time: 50 days for cast exhaust manifold

- Certification: ISO9001

High Performance Custom Ductile Iron Sand Casting ggg40

High Performance Custom Ductile Iron Sand Casting ggg40

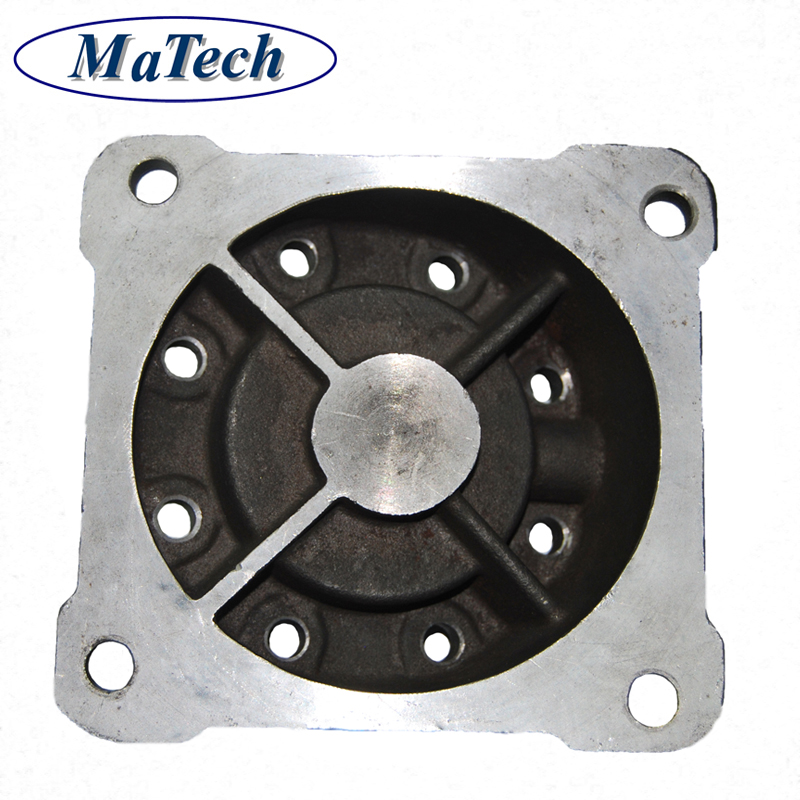

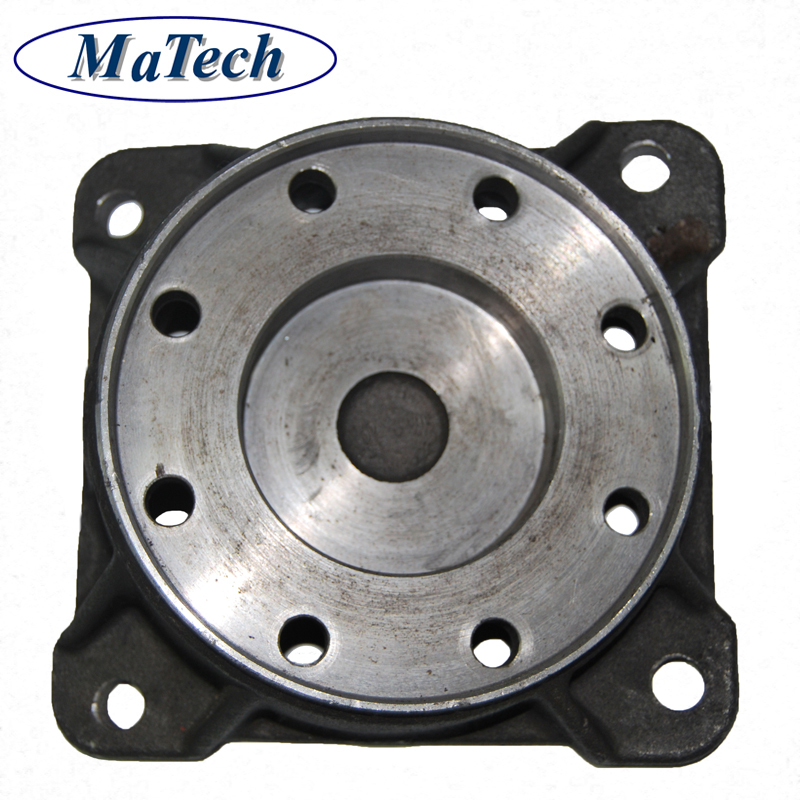

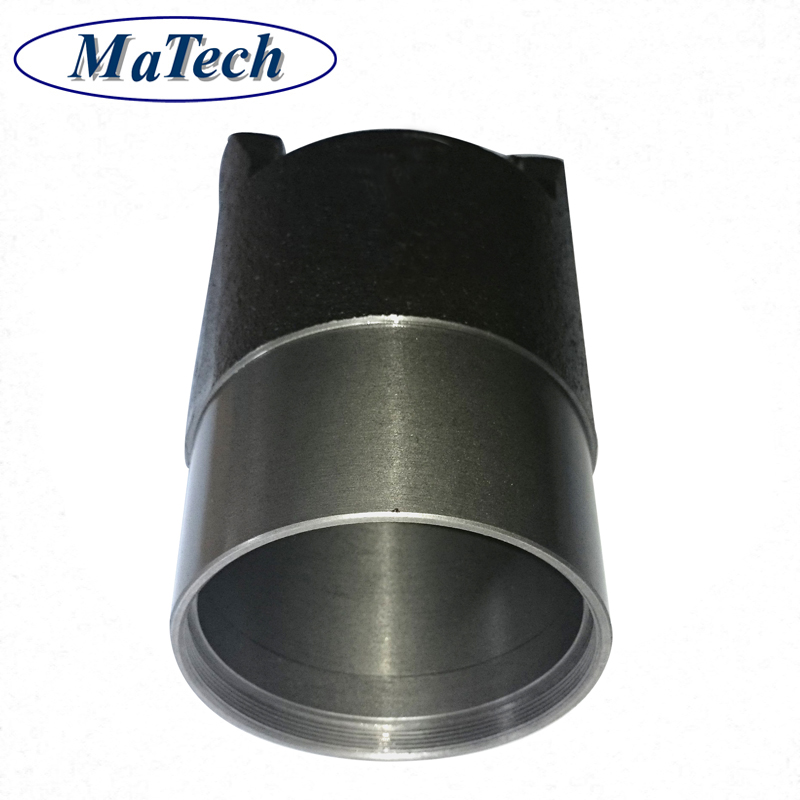

Item Name | High Performance Custom Ductile Iron Sand Casting ggg40 |

General Products Application/Service Area |

Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, transportation equipment, Valve and Pump system. Such as hot plate, engine bracket, truck chassis bracket, gear box , gear housing , gear cover, shaft, spline shaft , pulley, flange, connection pipe, pipe, hydraulic valve , valve housing ,Fitting , flange, wheel, fly wheel, oil pump housing, starter housing, coolant pump housing, transmission shaft , transmission gear, sprocket, chains etc.

|

Main blank Process for Casting | Sand Casting , Resin Sand Casting, Green Sand Casting, Shell Molding, Automatic Molding, Lost Wax Casting, Lost Foam Molding Casting |

Blanks Tolerance -Casting Tolerance | CT9-10 for Machine Molding Process, CT8-9 for Shell Molding and Lost Foam Molding Casting Process CT10-11 for Manual Molding Sand casting Process |

Applicable Material |

Ductile Iron Casting, Grey Iron Casting OR According to customer requirement

|

Casting Blank Size /Dimensions | 2 mm-2000mm / 0.08inch-79inch for casting iron, according to customer requirement |

Casting Blank Weight | Range from 0.01kg-1000kg for casting iron |

Applicable Machining Process | CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming /Grinding/Honing and etc. |

Machining Tolerance | From 0.005mm-0.01mm-0.1mm |

Machined Surface Quality | Ra 0.8-Ra3.2, according to customer requirement |

Applicable Heat Treatment | Normalization , annealing, quenching and tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching |

Applicable Finish Surface Treatment |

Shot/sand blast, polishing, Surface passivation, Primer Painting , Powder coating, ED- Coating, Chromate Plating, zinc-plate, Dacromat coating, Finish Painting.

|

MOQ of mass production | For ductile iron sand casting ggg40: 100pcs, or as clients required For Machining: 50pcs |

Lead Time | About 50 days for ductile iron sand casting ggg40 |

Ductile Iron Casting Material Comparison Table:

Cast iron with nomular graphite DIN EN 1563 | Germany DIN 1693 | France NF | Great Britain BS | Netherlands NEN | Sweden MNC | USA ASTM A536 |

EN-GJS-350-22-LT | GGG-35.3 | FGS 370-17 | 370/17 | GN 38 | 0717-15 | ---- |

EN-GJS-400-18-LT | GGG-40.3 | ---- | ---- | ---- | ---- | 60-40-18 |

EN-GJS-400-15 | GGG-40 | FGS-400-12 | 420/12 | GN 42 | 0717-02 | 60-40-18 |

EN-GJS-400-10 | ---- | ---- | 420/12 | ---- | ---- | 65-45-12 |

EN-GJS-500-7 | GGG-50 | FGS-500-7 | 500/7 | GN 50 | 0727-02 | 65-45-12/ 80-55-06 |

EN-GJS-600-3 | GGG-60 | FGS-600-3 | 600/3 | GN 60 | 0732-03 | 80-55-06 |

EN-GJS-700-2 | GGG-70 | FGS-700-2 | 700/2 | GN 70 | 0737-01 | 100-70-03 |

EN-GJS-800-2 | GGG-80 | FGS-800-2 | 800/2 | 120-90-02 | ||

EN-GJS-1000-5 (DIN EN 1564) | GGG-100B/A | ---- | ---- | ---- | ---- | 850-550-10 |

EN-GJS-AX NiSiCr35 5 2 | GGG- NiSiCr 35 5 2 | FGS- Ni35Si5Cr2 | S5S | ---- | ---- | Type D-5S |

Grey Iron Casting Material Comparison Table:

Cast iron with lamellar graphite DIN EN 1561 | Germany DIN 1691 | France NF | Great Britain BS | Netherlands NEN | Sweden MNC | USA ASTM A48 |

EN-GJL-150 | GG-15 | Ft 15 D | Grade 150 | GG 15 | 01 15-00 | 20 B / 25 B |

EN-GJL-200 | GG-20 | Ft 20 D | Grade 180/220 | GG 20 | 01 20-00 | 25 B / 30 B |

EN-GJL-250 | GG-25 | Ft 25 D | Grade 220/260 | GG 25 | 01 25-00 | 35 B / 40 B |

EN-GJL-300 | GG 30 | Ft 30 D | Grade 300 | GG 30 | 01 30-00 | 40B / 45 B |

1. What do you do?

We are a professional manufacturer with over 15 years’ export experience for designing and producing vehicle machinery parts.

2. How can I get some samples?

If you need, we are glad to offer you samples for free, but the new clients are expected to pay the courier cost, and the charge will be deducted from the payment for formal order.

3. Can you make ductile iron sand casting ggg40 according to our drawing?

Yes, we can make ductile iron sand casting ggg40 according to your drawing, 2D drawing, or 3D cad model. If the 3D cad model can be supplied, the development of the tooling can be more efficient. But without 3D, based on 2D drawing we can still make the samples properly approved.

4. Can you make ductile iron sand casting ggg40 based on our samples?

Yes, we can make measurement based on your samples to make drawings for tooling making.

5. What’s your quality control device in house?

We have spectrometer in house to monitor the chemical property, tensile test machine to control the mechanical property and UT Sonic as NDT checking method to control the casting detect under the surface of ductile iron sand casting ggg40.

We produce iron casting parts per your drawing or sample, with cost reduction and feasible tech proposals. Inquiry now!